The Expanding Importance of Electronic Packaging

Electronic packaging is no longer just about encasing a chip for protection. It has evolved into a core element of performance engineering, influencing speed, thermal stability, and long-term reliability. As devices shrink while processing demands increase, packaging must take on the dual role of protection and performance optimization. Modern innovations are reshaping how engineers approach design from the ground up.

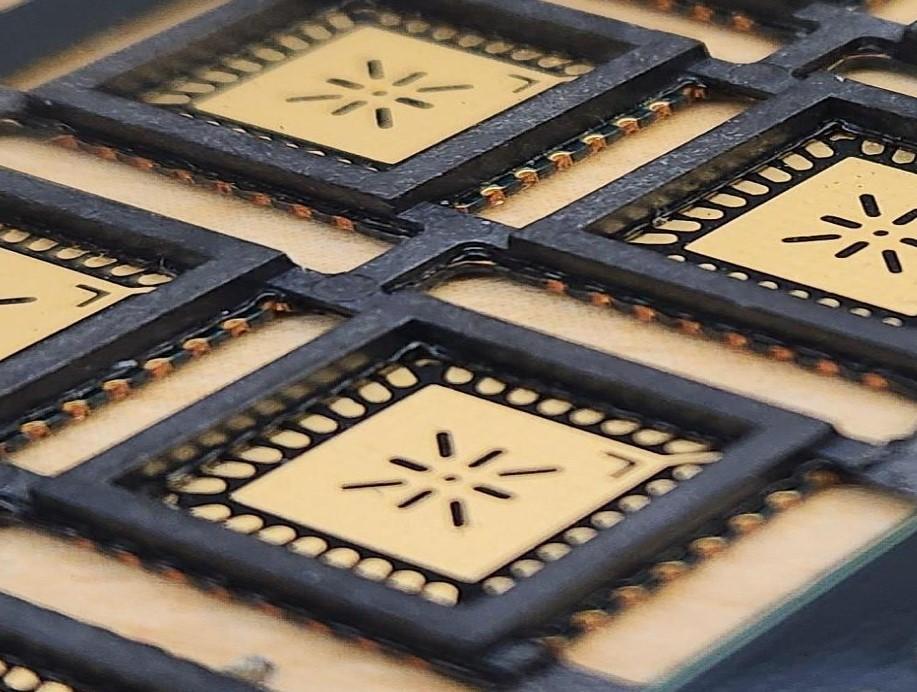

This design incorporates a sealed internal air space to reduce dielectric losses and enhance thermal dissipation. It has gained a reputation for delivering exceptional electrical performance, especially in high-frequency and high-power environments. Industries ranging from aerospace to telecommunications are adopting it for applications where precision and reliability are paramount.

The Rise of High-Frequency Demands in Modern Systems

With the growth of 5G, radar, and advanced satellite communications, the need for high-frequency operation has become a defining factor in packaging selection. At these frequencies, even tiny imperfections in the packaging material can distort signals and degrade system performance.One of the standout solutions in this area is air cavity package technology. Standard encapsulated packages can introduce signal loss that limits operational efficiency. This challenge has opened the door for advanced alternatives.

Packaging for high-frequency systems must provide a stable and predictable electrical environment. The geometry, material composition, and structural integrity all influence the final performance. High-end applications cannot afford any degradation that would compromise speed or accuracy. The push toward higher frequencies is therefore driving significant investment in packaging research and refinement.

How Material Science Shapes Packaging Success

The materials chosen for an electronic package play a critical role in determining its thermal and electrical characteristics. Metals like copper and alloys with high thermal conductivity help move heat away from the die efficiently. This heat management capability is essential in preventing performance loss or component damage. Material choice becomes even more crucial in systems with long operational lifespans.

Ceramics and low-loss dielectric materials are preferred for applications where signal clarity is vital. These materials allow electrical signals to pass with minimal interference, preserving high-speed performance. Engineers must also ensure that the materials are mechanically stable to withstand environmental stress. Selecting the wrong material could compromise both reliability and manufacturability.

The Link Between Packaging and System Accuracy

In many industries, precision is non-negotiable. Applications in aerospace guidance, defense radar systems, and medical imaging rely on the integrity of every signal transmitted. Even slight inconsistencies in timing or amplitude can disrupt the overall functionality of these systems. Packaging is often the hidden factor that determines whether a system meets or misses performance targets.

By using advanced designs, engineers can ensure that signals remain stable from the source to the receiver.Reduced interference and stable thermal conditions mean that mission-critical systems can operate with greater confidence.

Scalability and Manufacturing Adaptation

High-performance packaging must also be practical for mass production. A solution that performs flawlessly but requires entirely new production lines can be prohibitively expensive to implement. For widespread adoption, compatibility with existing manufacturing processes is a significant advantage. This allows companies to integrate new designs without disrupting workflow.

Air cavity packaging can be manufactured using surface-mount compatible processes, reducing the need for specialized equipment. This compatibility not only lowers costs but also shortens the product development cycle. Manufacturers can meet market demand faster, while still delivering advanced performance features.

Managing Thermal Load in Power-Dense Devices

As chips become more powerful, the thermal load they produce increases dramatically. Effective heat dissipation is crucial to maintain both performance and longevity. Without proper thermal management, components can overheat, leading to slower processing, signal distortion, and eventual failure. Packaging directly influences how well a system can handle this challenge.

Designs now integrate features like embedded heat spreaders and thermally conductive substrates. These features draw heat away from hotspots and distribute it evenly. By combining smart structural design with high-performance materials, engineers can create packages that manage extreme thermal demands without sacrificing size or weight efficiency.

Miniaturization and the Push for Integrated Systems

The demand for smaller, lighter devices has led to the concept of system-level integration. Rather than designing the chip and package separately, they are engineered as a unified system. This allows for optimized signal paths, better thermal control, and reduced power loss. It also enables more compact designs without compromising on capability.

By integrating components into a single package, engineers minimize the number of electrical interconnects. Fewer interconnects mean fewer points where signal loss can occur. This is particularly important in RF and high-speed digital systems where clarity and timing are crucial. Integration paves the way for more powerful yet portable devices.

Environmental Stress and Packaging Durability

Electronics used in harsh environments face challenges that go beyond simple performance metrics. Factors like temperature fluctuations, vibration, and moisture exposure can degrade even the most advanced components.The emergence of air cavity package technology represents a culmination of decades of incremental advances, combining the best features of prior designs with cutting-edge performance optimization. Packaging serves as the first line of defense against these environmental hazards. Durability is just as important as electrical efficiency in these cases.

Hermetic sealing and rugged materials ensure that moisture and contaminants cannot enter the package. Mechanical reinforcement prevents structural failures from vibration or impact. These durability features make such packaging indispensable for sectors like aerospace, military, and offshore energy, where reliability is mission-critical.

Historical Evolution of Packaging Design

The history of electronic packaging reflects the broader evolution of technology. Early devices relied on simple metal can enclosures, offering protection but little performance enhancement. As circuits became more complex, plastic-molded designs gained popularity for cost efficiency. However, these designs could not handle the demands of high-frequency, high-power systems.

The need for better electrical performance led to the development of ceramic and hybrid packages. These brought significant improvements in thermal and electrical stability.

The Role of Packaging in RF Testing and Validation

Testing high-frequency systems requires that the packaging not interfere with measurement accuracy. Poorly designed packaging can introduce distortions that mask the true performance of the device. This can lead to inaccurate test results and flawed design decisions. Packaging must therefore be designed with testing compatibility in mind.

Advanced RF-compatible packages ensure that test signals are transmitted and received without alteration. This accuracy allows engineers to fine-tune performance parameters with confidence. Reliable testing reduces development cycles and speeds up time-to-market, a vital consideration in competitive industries.

Cost-Benefit Considerations in Packaging Selection

While advanced packaging offers superior performance, it also comes with higher production costs. Manufacturers must carefully weigh the benefits against the financial impact. For mission-critical applications, the cost is often justified by the enhanced reliability and operational capability. However, for consumer products, cost efficiency may take priority.

By adopting scalable designs that can be adapted for different product tiers, companies can balance performance and budget. Modular approaches allow manufacturers to offer premium performance for high-end markets while maintaining affordability for general use. Strategic decision-making in this area can significantly affect overall profitability.

Sustainability and the Future of Packaging

As industries move toward greener manufacturing practices, sustainability is becoming an important factor in packaging design. Recyclable materials, reduced energy usage during production, and longer product lifespans all contribute to a smaller environmental footprint. Manufacturers are now evaluating packaging solutions not only on performance but also on environmental impact.

Research into biodegradable or easily recyclable packaging materials is advancing quickly. These materials must still meet rigorous performance requirements, especially in high-frequency applications. The challenge lies in combining sustainability with cutting-edge performance, but the industry is steadily making progress toward this goal.

Anticipating Next-Generation Packaging Innovations

The next wave of packaging innovation will likely involve further integration with semiconductor fabrication. Concepts such as chiplet-based architectures and 3D stacking will blur the line between the chip and its enclosure. This integration could dramatically improve speed, reduce latency, and lower power consumption.

Additionally, adaptive packaging that can monitor and respond to environmental conditions may emerge. Such designs could adjust thermal profiles or signal routing in real time to optimize performance. As computational demands grow, packaging will continue to be a driving force in the overall capabilities of electronic systems.

Conclusion: Packaging as a Performance Enabler

The evolution of electronic packaging has transformed it from a protective necessity into a performance enabler. Today’s most advanced designs not only shield components but actively enhance their function, reliability, and lifespan. From thermal management to signal integrity, packaging decisions shape the capabilities of the final device.

Among these solutions, air cavity package technology has proven to be one of the most effective for high-frequency, high-power, and mission-critical systems. Its balance of precision, scalability, and adaptability ensures it will remain at the forefront of electronic design. As the industry continues to evolve, the role of packaging will only grow in importance, defining the performance standards of the future.