The structure of a car bumper mould is a carefully engineered system designed to meet the dual requirements of strength and precision. Since bumpers are among the largest plastic components in a vehicle, the mould must support both dimensional accuracy and long-term durability under repeated use in production.

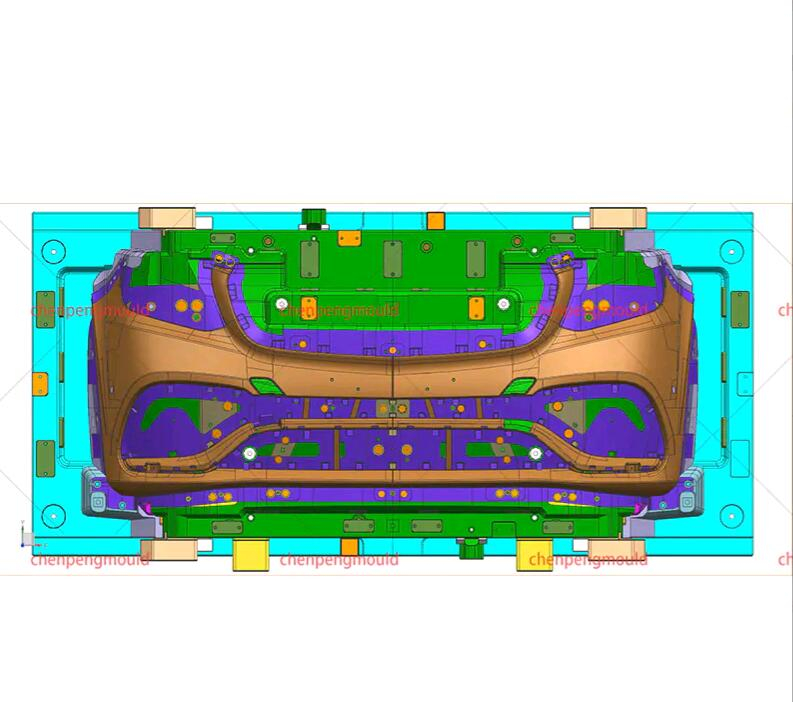

A typical bumper mould consists of a cavity side and a core side, which together form the shape of the bumper. The cavity side defines the exterior surface, while the core side shapes the interior structure. Cooling channels are strategically placed within both sides to ensure even temperature distribution during the injection process. This uniform cooling is essential for minimizing warpage and maintaining consistent part quality.

The mould is also equipped with a robust gating system that directs molten plastic into the cavity. Balanced flow is critical, as uneven filling can result in defects such as weld lines or air traps. In addition, ejector pins and plates are integrated into the design to release the finished bumper smoothly without surface damage. Reinforcing components, such as guide pillars and bushings, help maintain alignment and stability during repeated cycles.

Given the large size of car bumpers, moulds are typically constructed from high-strength steel to withstand pressure and wear. Attention is also given to maintenance access, as polishing and repair are often required to preserve surface quality.

The structure of a car bumper mould reflects a balance between precision engineering, material performance, and efficient production needs.

https://www.bumpermould.net/product/bumper-mould/no-flash-mercedesbenz-gls-maybach-front-bumper-mould.html

Why choose us?

Experience: We have had strong expertise in designing and developing automotive injection molds since 2000. Our company has developed 1000 bumper molds, including Volkswagen, Audi, Mercedes, BMW, Toyota, Ford, Skoda, etc. Moreover, we also developed higcarsbumper bumpers, like Rolls-Royce, Lamborghini I, Porsche Panam, er, an, etc.

Performance: Our bumper molds consistently deliver higher precision and quality in the molded parts compared to others.

Uniqueness:O ur bumper molds have unique features and innovations that set them apart. It includes advanced cooling systems, innovative design elements, and special coatings that improve durability and reduce cycle times.

Quality AssAssurancestressesss our commitment to quality assurance processes and standards that ensure the reliability and consistency of our bumper mold's output.