Carbide machining inserts play a significant role in modern manufacturing processes by providing durable cutting surfaces for a wide range of materials. These inserts are composed of tungsten carbide and cobalt, which combine hardness with toughness, allowing them to handle high-speed machining without significant wear. In metalworking operations, carbide inserts are used for turning, milling, and drilling, offering consistent performance across repetitive tasks.

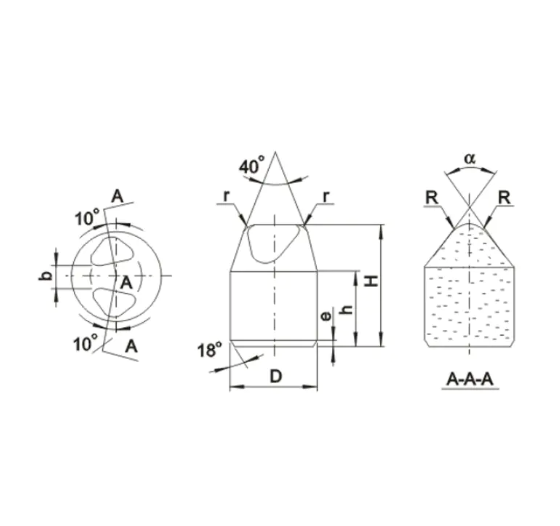

The geometry of carbide machining inserts is carefully designed to improve chip removal and reduce cutting forces. Various shapes, including triangular, square, and round, can be selected based on the material being processed and the machining operation. Coatings such as titanium nitride or aluminum oxide are often applied to enhance surface hardness and reduce friction, which can extend tool life.

In addition to material composition, insert grades are chosen according to workpiece properties. Carbide inserts provide reliable performance on hard metals such as stainless steel, hardened steel, and cast iron, while also being capable of machining softer alloys efficiently. By selecting the appropriate insert, manufacturers can achieve better surface finish and reduce downtime due to tool changes.

Maintenance of carbide machining inserts is also crucial. While they are known for durability, monitoring wear patterns can help determine the right time for replacement. Using inserts within their recommended speed and feed ranges ensures consistent machining results and minimizes the risk of damage to both the insert and the workpiece.

Carbide machining inserts are a versatile solution for industrial machining applications. Their combination of hardness, toughness, and wear resistance allows manufacturers to maintain efficiency and precision. The continuous development of insert geometries and coatings further supports evolving machining demands, ensuring that operations remain productive and reliable.