Choosing an appropriate IML mould requires careful evaluation of several technical factors. The product design must be analyzed to determine optimal IML mould cavity configurations that ensure proper label placement and material flow. The size and complexity of the intended product influence the IML mould design, particularly regarding label positioning systems and ejection mechanisms. Material selection for the IML mould components must consider wear resistance and thermal conductivity to maintain performance throughout the production lifecycle. These fundamental considerations help ensure the specified IML mould will meet production requirements while maintaining consistent quality output.

Label handling and placement systems are critical aspects of IML mould design. The IML mould must interface precisely with robotic systems that position labels within the cavities before each injection cycle. Vacuum systems within the IML mould help secure labels in position during mould closing and injection phases. The design of these label management systems in the IML mould affects production speed, registration accuracy, and overall process reliability. The integration of these components requires careful engineering to ensure the IML mould operates efficiently within the broader manufacturing system, maintaining synchronization between label placement and injection processes.

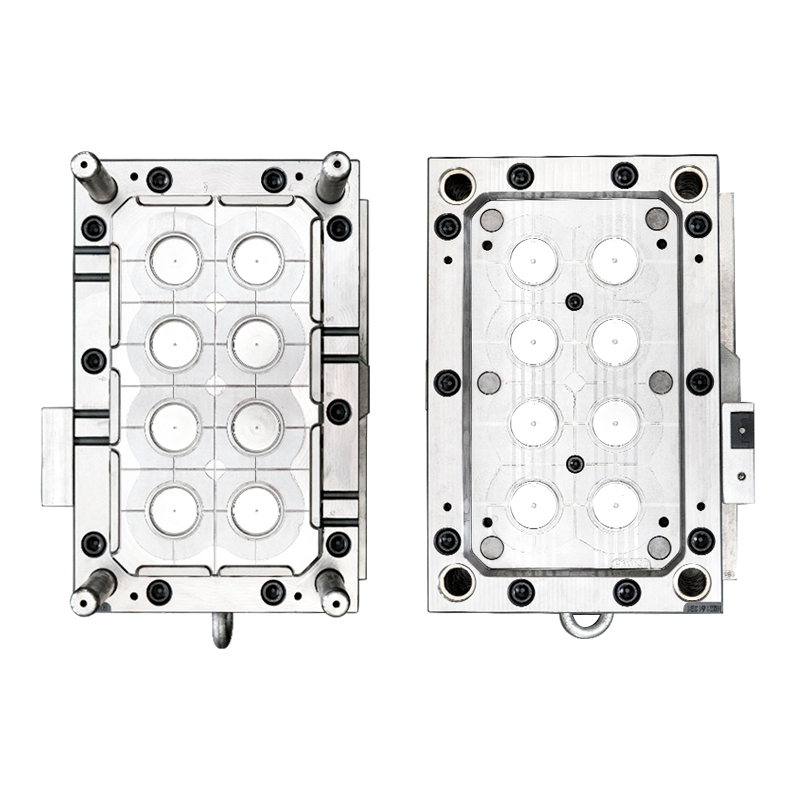

Production requirements significantly influence IML mould specifications. Expected production volumes determine the durability requirements for IML mould components and the sophistication of cooling systems needed to maintain cycle times. The type of plastic material being processed affects the thermal management needs of the IML mould design. Label characteristics including material composition, thickness, and adhesive properties influence cavity design and venting requirements in the IML mould. These production factors must be thoroughly evaluated to ensure the IML mould will perform reliably under actual manufacturing conditions while meeting quality expectations for finished products.

Maintenance and operational considerations complete the IML mould selection process. The design should allow for accessible maintenance of critical components such as ejection systems, vents, and cooling channels within the IML mould. Compatibility with existing manufacturing equipment and processes affects how the IML mould will integrate into production operations. Future product change requirements might suggest modular IML mould designs that allow for cavity modifications rather than complete tool replacement. These practical considerations help ensure the selected IML mould provides long-term value through reliable performance, maintainability, and adaptability to potential future production needs.