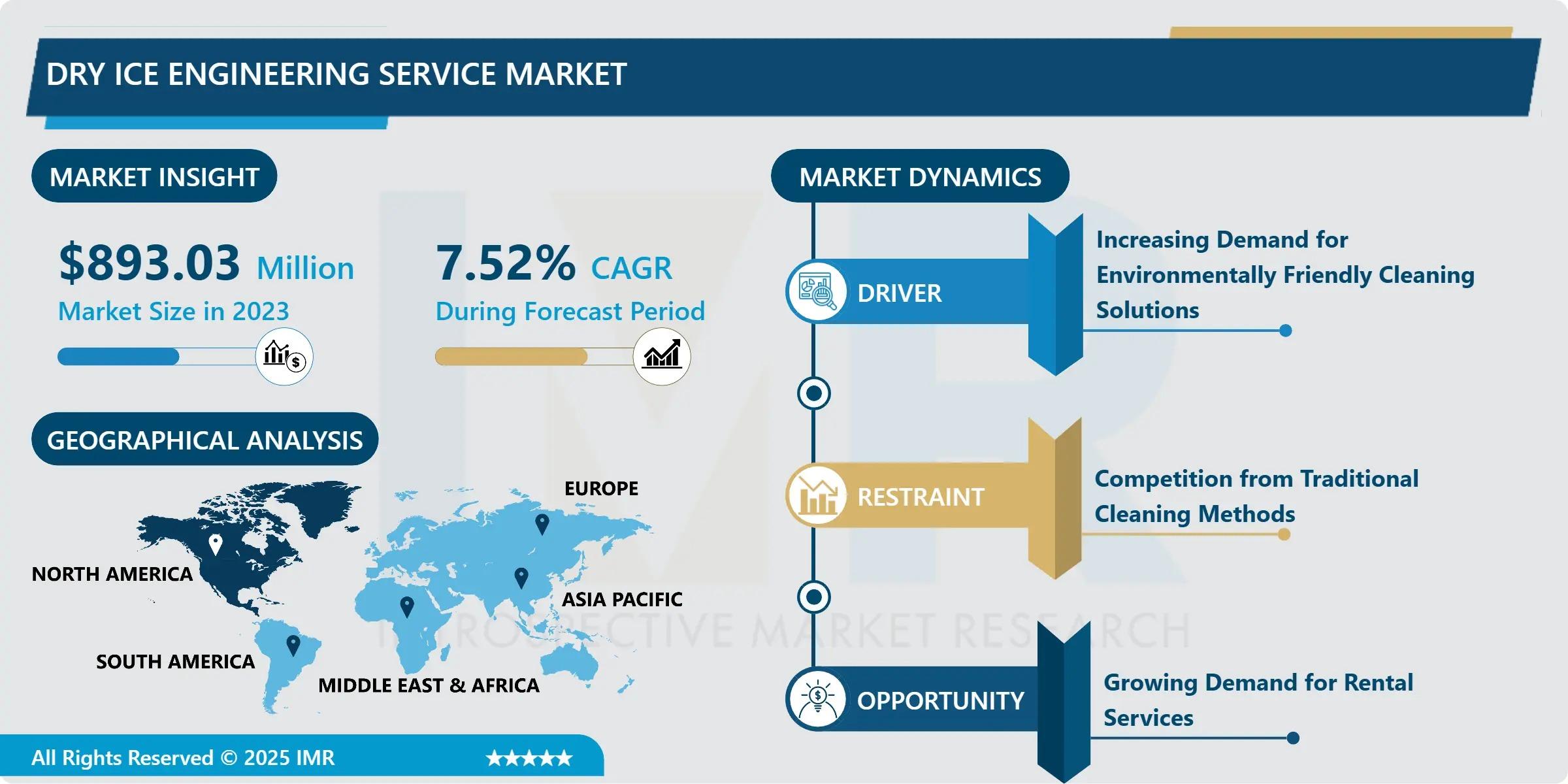

“According to a new report published by Introspective Market Research, titled, Dry Ice Engineering Service Market by Product Type, Application, and Region, The Global Dry Ice Engineering Service Market Size Was Valued at USD 960.19 Million in 2024 and is Projected to Reach USD 11,927.8 Million by 2032, Growing at a CAGR of 38.24%.”

2. Introduction / Market Overview

The Dry Ice Engineering Service Market encompasses specialized services related to the production, handling, delivery, and advanced application of dry ice (solid carbon dioxide), primarily focusing on industrial cleaning and preservation solutions. These services involve custom-designed equipment and technical expertise for dry ice blasting, often referred to as dry ice cleaning, which utilizes recycled CO2 pellets accelerated at high speed to clean surfaces. This process is highly valued because the dry ice instantly sublimates (turns directly into gas) upon contact, leaving no secondary waste, moisture, or chemical residue.

Compared to traditional cleaning methods that rely on abrasive materials, water, or harsh solvents, dry ice engineering services offer superior, non-abrasive cleaning results, ensuring the integrity of sensitive equipment. Key advantages include reduced downtime (as equipment can often be cleaned while hot and in place), non-conductivity, and its eco-friendly nature, making it ideal for precision maintenance in high-value industries. Furthermore, engineering services support ultra-low temperature cold chain logistics essential for pharmaceuticals and complex food preservation.

Dry Ice Engineering Service solutions are rapidly becoming critical in sectors where hygiene, precision, and minimizing environmental impact are paramount. Key sectors include the Automotive, Aerospace, Power Generation, Food & Beverage, and Pharmaceutical industries. Its main use lies in maintaining operational efficiency by rapidly cleaning complex machinery, preparing surfaces for coating, and ensuring stringent compliance with environmental and hygiene regulations across global supply chains.

3. Market Segmentation

The Dry Ice Engineering Service Market is segmented into Product Type, Application, and Region. By Product Type, the market is categorized into (Pellets, Blocks, Slices/Slabs). By Application, the market is categorized into (Industrial Cleaning, Storage & Transportation, Food & Beverage, Healthcare). By Region, the market is categorized into (North America, Asia-Pacific, Europe).

4. Growth Driver

The primary growth driver for the Dry Ice Engineering Service Market is the increasing global demand for sustainable and residue-free industrial cleaning and surface preparation solutions. Environmental regulations across North America and Europe are becoming more stringent, forcing manufacturers in automotive, aerospace, and power generation to phase out chemical and abrasive cleaning agents that generate hazardous waste. Dry ice blasting, which uses recycled CO2 and eliminates secondary waste disposal costs, aligns perfectly with corporate sustainability goals and reduces water consumption by up to 90% compared to traditional washing methods, thereby accelerating its adoption for critical maintenance tasks.

5. Market Opportunity

A key market opportunity lies in the ongoing integration of automation and Industry 4.0 technologies within industrial cleaning processes. As manufacturers adopt robotics and smart factories, dry ice engineering firms are responding by developing and offering automated, in-line dry ice blasting systems equipped with Internet of Things (IoT) sensors. These integrated systems allow for real-time monitoring of cleaning performance, predictive maintenance scheduling, and remote adjustment of blasting parameters. This technological leap enables ultra-precision cleaning for sensitive components (like those in electronics and composites) at scale, significantly improving process consistency and minimizing human error.

6. Detailed Segmentation

Title: Dry Ice Engineering Service Market, Segmentation

Line below: The Dry Ice Engineering Service Market is segmented on the basis of Product Type, Application, and Region.

Product Type The Product Type segment is further classified into Pellets, Blocks, and Slices/Slabs. Among these, the Pellets sub-segment accounted for the highest market share in 2024. This dominance is attributed to the versatility and handling efficiency of dry ice pellets. Their small, uniform size makes them ideal for use in dry ice blasting equipment for industrial cleaning, enabling precision cleaning in hard-to-reach spaces. Furthermore, pellets are the preferred form for deep-freeze cold chain logistics in the pharmaceutical and food sectors, where their high surface area provides efficient and stable temperature maintenance for temperature-sensitive goods during transit.

Application The Application segment is further classified into Industrial Cleaning, Storage & Transportation, Food & Beverage, and Healthcare. Among these, the Industrial Cleaning sub-segment is anticipated to show the fastest growth by 2032. The expansion is fueled by the continuous need for non-destructive maintenance of high-value capital equipment in sectors like power generation, automotive manufacturing, and specialized aerospace component cleaning. The ability of dry ice cleaning to quickly remove residues, paints, and contaminants without damaging the substrate or creating secondary waste makes it the preferred method for minimizing facility downtime and extending equipment lifespan.

📊 𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐅𝐫𝐞𝐞 𝐏𝐃𝐅 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭𝐬:https://introspectivemarketresearch.com/request/15674

7. Some of The Leading/Active Market Players Are-

- Linde plc (US)

- Air Liquide (France)

- Air Products and Chemicals Inc. (US)

- Cold Jet LLC (US)

- Continental Carbonic Products, Inc. (US)

- Messer Group GmbH (Germany)

- Airgas Inc. (US)

- ASCO CARBON DIOXIDE LTD. (Switzerland)

- Polar Ice Ltd. (Ireland)

- HORECO2 (China)

- Ice Field Dry Ice Engineering GmbH (Germany)

- Reliant Dry Ice (US)

and other active players.

8. Key Industry Developments

News 1: In February 2024, Cold Jet introduced new dry ice cleaning technology aimed specifically at the composite industry at JEC World 2024. This development addresses the challenge of maintaining and preparing sensitive composite tooling and parts without causing abrasion. The new system emphasizes non-abrasive, sustainable cleaning solutions, proving dry ice technology’s crucial role in precision surface preparation prior to bonding or coating processes in high-tech manufacturing.

News 2: In December 2022, ASCO CARBON DIOXIDE LTD. launched an innovative dry ice pellet refilling system designed for high precision and accuracy in dosing pellets into small containers. This technological advancement improves efficiency and reliability for specialized applications, such as small-scale pharmaceutical or laboratory use, bolstering the ability of dry ice engineering service providers to meet stringent demands for customized, precise cold storage solutions.

9. Key Findings of the Study

- Dominant segments: Pellets (Product Type) and Industrial Cleaning (Service Application) currently hold the largest shares.

- Leading regions: North America remains the largest market, while Asia-Pacific (APAC) is projected to record the fastest growth due to rapid industrialization.

- Key growth drivers: Increasing adoption of microservices architectures and demand for superior observability and security.

- Market trends: Strong industry momentum toward multi-cloud and hybrid cloud deployment models that require cross-platform mesh control.

- Key growth drivers: Global shift towards sustainable and residue-free industrial cleaning and the expansion of cold chain logistics.

- Market trends: Integration of automation (robotics and IoT sensors) into dry ice blasting equipment for in-line, precision cleaning in high-tech industries.