The essential purpose of outdoor lighting extends beyond mere illumination to encompass fundamental safety considerations that protect both people and property. Recent discussions within facilities management circles have highlighted alarming instances where inadequate protection in outdoor fixtures led to dangerous situations during extreme weather events. These situations reveal the critical importance of implementing proper safety standards in lighting products designed for outdoor or damp locations. The fundamental safety characteristic of a properly certified Ip65 Waterproof Fixture lies in its engineered protection against moisture ingress and its secure electrical isolation systems. When manufacturers compromise on these essential safety features, the results can extend beyond product failure to create genuinely hazardous conditions that endanger maintenance personnel and the public. This reality underscores why proper certification and rigorous manufacturing standards matter significantly for products installed in areas where water exposure represents a constant threat to electrical safety.

Manufacturing lighting solutions that genuinely protect against electrical hazards requires more than basic compliance with minimum standards. It demands a comprehensive approach to safety engineering that considers all potential failure modes and environmental challenges. The development process must incorporate robust isolation barriers, secure connection systems, and multiple layers of protection against moisture penetration. Quality manufacturers implement thorough testing protocols that simulate extreme conditions far beyond normal operational requirements. These tests verify that electrical components remain completely isolated from moisture even under severe pressure differentials or temperature variations. The manufacturing process itself must maintain strict controls to ensure consistent application of seals and gaskets, proper torque on connections, and complete verification of insulation integrity. This meticulous approach to safety engineering represents the difference between products that merely claim protection and those that genuinely deliver it.

Facility managers and electrical specifiers bear significant responsibility for selecting products that ensure safety in challenging environments. The evaluation process should include careful examination of certification documentation, manufacturing quality controls, and design features that prevent moisture ingress. Reputable manufacturers provide transparent information about their safety testing protocols and certification compliance. They understand that different installation environments present unique challenges and offer specific guidance on proper product selection and installation techniques. These manufacturers typically employ independent third-party verification of their safety claims, providing additional assurance that their products will perform as expected in real-world conditions. The best manufacturers view safety not as a marketing feature but as a fundamental responsibility that guides every aspect of their design and manufacturing processes.

The relationship between specifiers and manufacturers should be built on mutual commitment to safety and quality. The most successful partnerships involve open dialogue about specific environmental challenges and performance requirements. Manufacturers who excel in safety engineering welcome questions about their design principles and testing methodologies. They provide detailed documentation of their safety features and explain how their products address common failure modes observed in outdoor installations. This collaborative approach ensures that specifiers can make informed decisions based on comprehensive understanding of product capabilities and limitations.

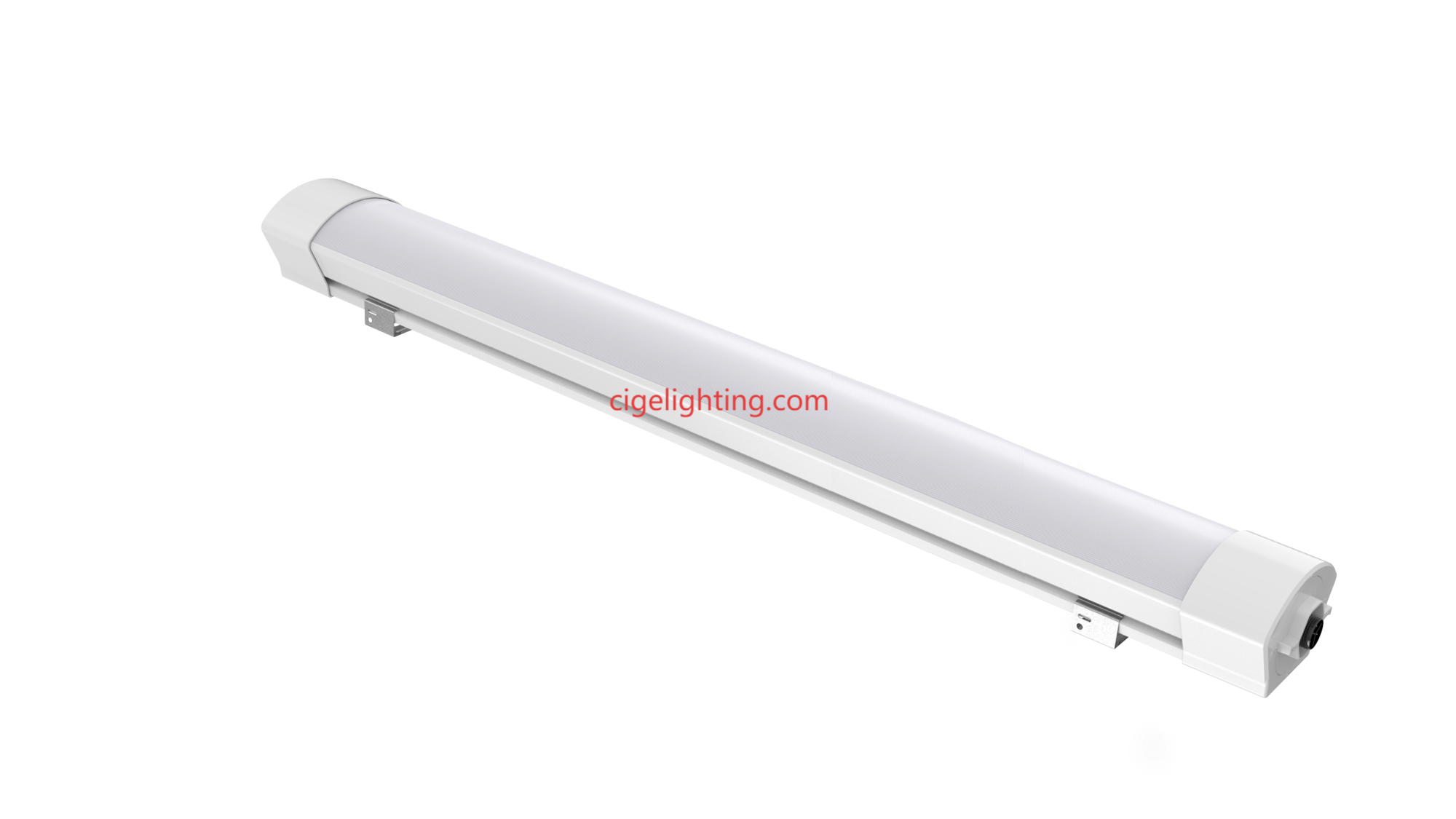

At Cigelighting, we believe that electrical safety represents the most critical aspect of outdoor lighting design. Our engineering team prioritizes safety through robust isolation systems, superior sealing technologies, and rigorous testing protocols that exceed standard requirements. We implement comprehensive quality controls throughout our manufacturing process to ensure consistent performance of every safety feature. Our commitment to excellence ensures that every Ip65 Waterproof Fixture we produce provides reliable protection against electrical hazards in wet conditions. Choose Cigelighting for lighting solutions that demonstrate unwavering commitment to safety through superior engineering and manufacturing excellence.Click https://www.cigelighting.com/product/ to reading more information.