A self-sucking pump represents an important advancement in fluid handling technology. Unlike conventional pumps that require manual filling before operation, this pump can automatically draw water into its system after the first use. This feature makes it ideal for applications such as irrigation, household water supply, and wastewater drainage where ease of use and reliability are key.

The internal mechanism of a self-sucking pump includes an impeller and a specially designed casing that allows air and water to mix during the priming stage. When the pump starts, the rotation of the impeller generates a pressure difference that draws liquid from the source. Once the suction pipe is filled, the pump transitions smoothly to normal operation, providing stable flow and discharge.

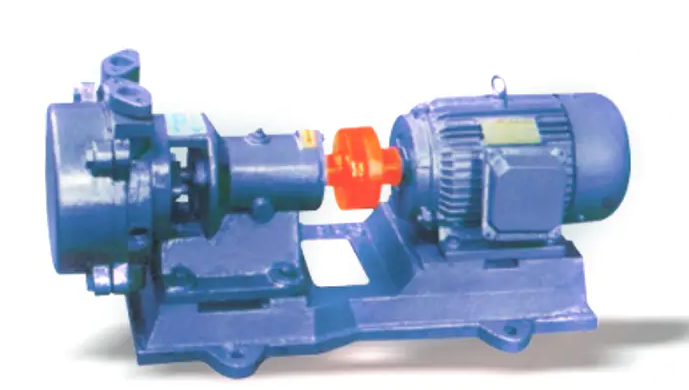

Factories producing self-sucking pumps pay close attention to material quality and performance testing. Each unit is typically inspected for flow rate, suction height, and pressure output. The choice of materials—ranging from corrosion-resistant metals to high-strength polymers—ensures that the pumps can operate under a variety of environmental conditions. Additionally, motor efficiency and noise reduction are important factors in design improvements.

Self-sucking pumps are valued for their versatility. They are used in agriculture for transferring irrigation water, in households for boosting water pressure, and in construction sites for dewatering. Some models are designed with thermal protection and mechanical seals to prevent overheating and fluid leakage. These safety features contribute to steady and dependable operation.

From an engineering standpoint, innovations in impeller geometry and flow path design have enhanced hydraulic performance. Factories also focus on simplifying maintenance—components such as seals and bearings are made easily accessible for inspection and replacement. This reduces downtime and ensures that the pump remains in service longer.

Environmental considerations are increasingly influencing pump design. Energy-saving motors and recyclable materials are being introduced to reduce the ecological impact of manufacturing. The self-sucking pump’s ability to minimize water waste through efficient suction cycles also supports sustainable water management practices.

Zhejiang Chuangken Fluid Co., Ltd. has developed a comprehensive range of self-sucking pumps that integrate durability, precision, and efficiency. The company continues to refine its technology to meet diverse pumping requirements in domestic and industrial sectors.