In modern web handling systems, the Aluminum Roller is a critical component for achieving consistent performance, and cbbmachine’s solutions continue to meet the high demands of industrial applications across multiple sectors.

This roller type is widely known for its excellent balance between strength and lightweight properties. The use of aluminum allows for high-speed operation without adding excessive rotational inertia, which helps reduce motor strain and energy consumption. Because aluminum dissipates heat efficiently, it also reduces thermal distortion in applications involving friction or elevated temperatures.

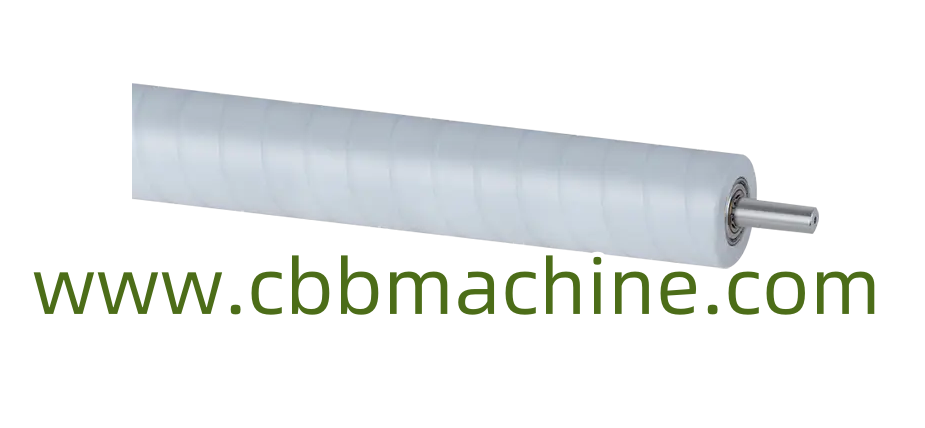

cbbmachine designs its aluminum rollers with precision to meet the specific needs of printing, laminating, slitting, textile, and packaging machinery. Each roller is CNC-machined to exact tolerances, ensuring smooth rotation and minimal vibration even at high line speeds. Surface treatments, including anodizing or Teflon coatings, can be applied to meet different material compatibility and anti-stick requirements.

One of the biggest advantages of aluminum rollers is their corrosion resistance. Unlike steel rollers, which require constant maintenance in humid or chemically exposed environments, aluminum rollers maintain performance over time with minimal upkeep. This makes them ideal for cleanroom production, food processing, and pharmaceutical packaging environments where hygiene and low contamination risk are essential.

The versatility of cbbmachine’s engineering allows for different core designs and dynamic balancing options. Whether you need dead-shaft, live-shaft, or air-shaft compatible rollers, each roller is optimized for mechanical strength and straightness, which are crucial for web alignment and edge control. The improved web handling performance translates into better print registration, lamination consistency, and reduced product defects.

Additionally, aluminum rollers play an important role in reducing downtime. Their reduced weight allows for quicker installation and changeovers during maintenance or product setup. This is particularly valuable in production lines that run multiple materials or require frequent format changes.

Another key benefit is the noise reduction during operation. Aluminum rollers are quieter compared to heavier metal alternatives, especially when combined with precision bearings and smooth surface finishes. This helps create a more pleasant work environment while supporting machine reliability.

Companies investing in modern automation systems should not overlook the impact of well-designed aluminum rollers on their overall production efficiency. When integrated properly, they contribute to smoother material flow, faster line speeds, and long-term cost savings.

Explore how cbbmachine can provide durable, customizable, and high-performance aluminum rollers tailored to your equipment by visiting: www.cbbmachine.com