The common and widely used mould for manufacturing cable ties is the injection mould. This mould is specifically designed for the injection moulding process, where plastic material is heated until it becomes molten and then injected into the mould cavity under high pressure. The mould itself is typically made of durable steel or aluminum to withstand the intense heat and pressure during production.

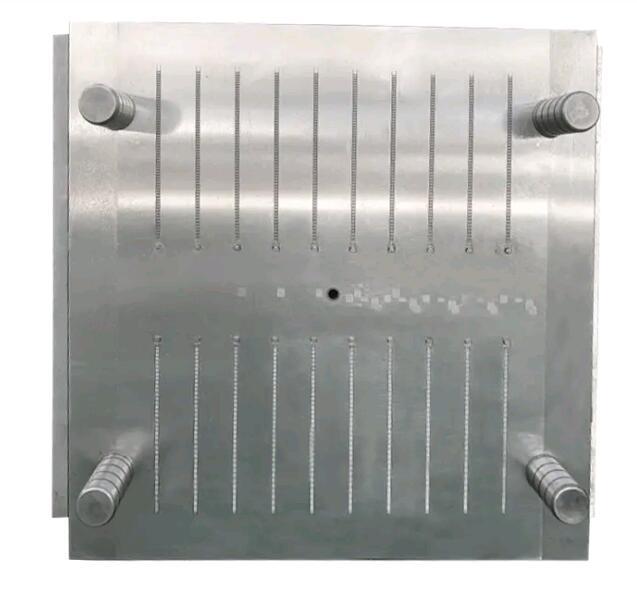

Injection moulds for cable ties are available in various configurations, depending on the design and size of the tie. Some moulds are designed to produce a single cable tie at a time, while others can produce multiple cable ties simultaneously, increasing production efficiency. The cavity design, along with cooling systems within the mould, ensures that the cable ties harden properly once the molten plastic is injected, resulting in a high-quality, finished product.

In large-scale production settings, manufacturers often turn to multi-cavity moulds to produce several cable ties in one cycle. These moulds are designed with multiple cavities, each capable of forming a separate cable tie. By using multi-cavity moulds, manufacturers can significantly increase the production rate, meeting the high demand for cable ties in various industries.

Multi-cavity cable tie moulds come in different configurations, such as two-cavity, four-cavity, and even eight-cavity moulds. The number of cavities in a mould is usually determined by the size of the cable ties being produced and the production capacity required. These moulds are often equipped with advanced cooling systems to ensure that the plastic material solidifies uniformly across all cavities, reduce the risk of defects

Hot runner moulds are another advanced type of cable tie mould used in high-precision injection moulding. In a hot runner system, the plastic material remains molten as it travels through the runners, ensuring a continuous flow of material into the cavities. This eliminates the need for cold runners (where plastic material solidifies in the runner channels), resulting in less waste and more efficient production.

Hot runner cable tie moulds are particularly beneficial when producing high volumes of cable ties in a consistent, high-quality manner. The hot runner system maintains precise control over the temperature of the plastic material, ensuring that each cable tie is produced with the correct shape and dimension. Furthermore, because the system minimizes material waste, manufacturers can achieve cost savings in terms of raw materials.

https://www.automobiletiemould.com/product/pp-seal-cable-tie-mold/threeplate-mold-split-cable-tie-mold-plastic-pp-seal-logistics-sign-cable-tie-tag.html

The PP Seal Cable Tie Mold features a three-plate mold split system, which is an advanced design for the production of plastic cable ties. This system allows for efficient and precise molding operations, reducing production time and maintenance costs.

The mold is designed to produce cable ties made from polypropylene (PP), a material known for its strength, durability, and resistance to chemicals. The choice of PP ensures that the cable ties produced by the PP Seal Cable Tie Mold offer performance and long-term stability.