The tape cutting machine has become an essential piece of equipment in industries that require precise and efficient tape processing. Known for its ability to handle various adhesive and non-adhesive materials, the machine’s performance characteristics determine how well it serves in fast-paced production and packaging environments.

One of the most important performance aspects of a tape cutting machine is its cutting accuracy. The ability to deliver uniform, clean cuts directly affects the quality of the finished product, whether in electronics assembly, packaging, or automotive component preparation. Advanced models maintain consistent cutting lengths even with continuous, high-speed operation.

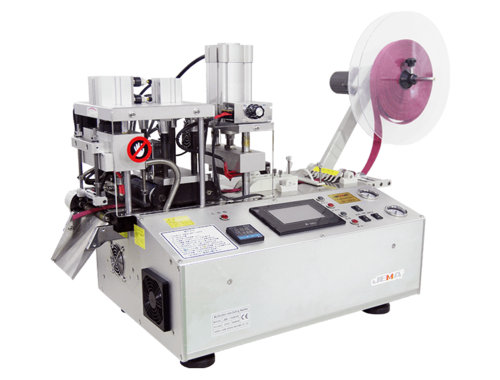

Another valuable feature is adjustable cutting speed and length control. Modern tape cutting machines offer flexible settings, allowing users to customize the machine according to different tape types and production requirements. This makes it suitable for handling both light-duty and heavy-duty materials with ease.

The tape feeding mechanism plays a key role in operational performance. A well-designed feeder ensures that tape is supplied smoothly without slipping or jamming, which minimizes interruptions and improves workflow. Some machines feature automatic sensors or programmable systems that adjust feed rates for different tape sizes and materials.

Durability is equally essential in performance evaluation. A good tape cutting machine should be built with sturdy materials and reliable motors capable of withstanding continuous use in industrial environments. Components such as cutting blades should be replaceable and easy to maintain, ensuring long-term productivity.

User-friendly operation is another important feature. Machines equipped with clear control panels, adjustable settings, and safety mechanisms contribute to a smoother, safer, and more efficient work process.

In conclusion, a tape cutting machine delivers value through precise cutting, adjustable performance settings, reliable tape feeding, and durable construction. These features make it an indispensable tool for businesses seeking consistent quality and operational efficiency in tape-related applications.