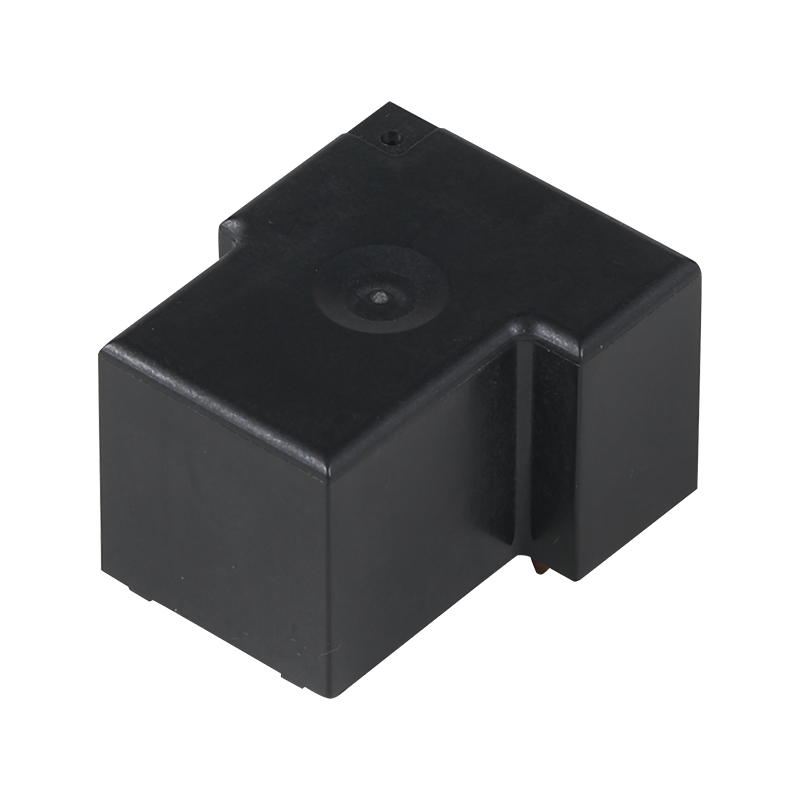

Electrical systems rely on components that perform consistently under varying conditions. A Customized Mold for Relay Socket plays a pivotal role in ensuring these standards are met. Unlike off-the-shelf alternatives, a tailored mold addresses specific engineering challenges, resulting in higher-quality relay sockets. This precision directly impacts the safety and efficiency of electrical installations.

One of the key reasons to use a Customized Mold for Relay Socket is to achieve tighter tolerances. Generic molds may produce sockets with slight variations, leading to loose connections or poor conductivity. A custom solution eliminates these inconsistencies by adhering to exact measurements. This precision is especially important in high-voltage applications where even minor deviations can cause malfunctions.

Durability is another critical factor influenced by a Customized Mold for Relay Socket. Standard molds may not account for environmental stressors like humidity, temperature fluctuations, or vibration. A bespoke mold can integrate reinforced structures or specialized materials to enhance resilience. This ensures that relay sockets maintain their integrity over time, reducing maintenance costs and downtime.

The manufacturing process also becomes more efficient with a Customized Mold for Relay Socket. Mass-produced molds often require post-production adjustments, adding unnecessary steps. A dedicated mold streamlines production by delivering components that meet specifications without additional modifications. This efficiency is particularly valuable for high-volume orders where time savings translate into significant cost reductions.

Safety is a major concern in electrical engineering, and a Customized Mold for Relay Socket contributes to risk mitigation. Poorly manufactured relay sockets can overheat, leading to potential fire hazards. A precision-crafted mold ensures proper insulation and contact alignment, minimizing these risks. Industries such as medical equipment and renewable energy rely on such reliability to prevent catastrophic failures.

Innovations in molding technology further enhance the capabilities of a Customized Mold for Relay Socket. Techniques like multi-cavity molding allow for simultaneous production of multiple units without sacrificing accuracy. This scalability is ideal for manufacturers looking to increase output while maintaining strict quality controls.

The decision to use a Customized Mold for Relay Socket comes down to performance and safety. By focusing on exact specifications and material excellence, businesses can produce relay sockets that exceed industry standards. Whether for industrial machinery or consumer electronics, a custom approach ensures long-lasting, dependable performance.